|

|

|

|

|

|

|

||||||||||

Vespa KitsSmall Frame: Large Frame: Installations: Malossi 210 Porting |

Vespa P200/PX200 - Malossi 210 PortingMy brother's birthday was coming up and he had always wanted to transform his daily rider into a tricked out P-Series. He had some money to spend earlier in the year and bought a Malossi 210 kit and put it on a shelf until he could afford all the other goodies. We thought we'd give him a hand by buying him some ported electric start P200 casings as a present.

These casings came brand new with porting work done by MB Developments (Note that MB Developments don't do Vespa tuning or parts sales anymore) and shipping for less than what is charged for new non-electric start casings in the US without shipping! Although I will try opening my own ports when I get a 210 for my VBA it made more sense to have a professional tuner do it for a present for someone else. I'd also like a little practice on some dead casings before I attack brand new ones. We chose electric start casings because an electric start is quite easy to add once the casings are able to accommodate the small electric starter motor. The it is just a matter of locating a special flywheel, stator, starter motor, and rectifier, and then wiring it in. There are 3 ports in a P200 crankcase mouth but only one that is used. The left and right transfers cast into the casing are not used because the two main transfers are cast within the P200 barrel. So why are these on P200s?? I think it is because a P125 and P200 share the same initial castings but then they become different internally when they are machined for different engine sizes. The P200 barrel spigot covers these two transfers anyway so there is no detrimental effect leaving them in the casting. The upper most transfer leads to is a smaller boost port in the barrel and the transfer is visible at the mating face between the barrel and the crankcase mouth. Because of this a standard P200 base gasket only has a single cut out. The P200/Rally 200 barrel is a little funny because it is rotated off the line of the crankshaft. Most two strokes and older Vespas have the exhaust port at 6:00, and the two main transfers at 3:00 and 9:00. The P200 is rotated by about 25 degrees probably to allow the exhaust to stick out at an angle rather than straight down..at least that is my best guess.

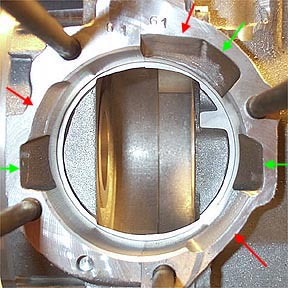

The porting work that MB Developments did is shown in the picture above. The original cast transfers are shown with green arrows, and the expansion of each one is shown with a red arrow. The Malossi kit has large openings in the spigot that now align properly and will allow a better gas flow to ports in the barrel wall. We will further this a little by polishing the ports to a fine finish.

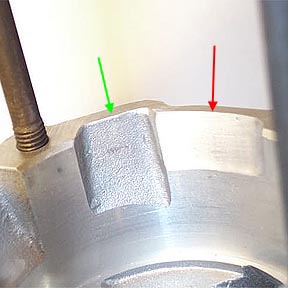

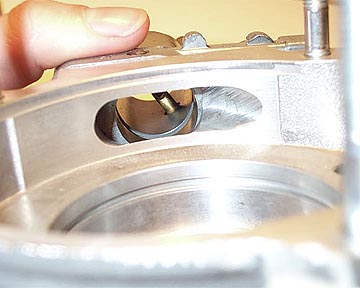

Above is a close up view of the clutch side main transfer before polishing, with the arrows for old and new. You can see the cast finish on the original transfer compared to the finish of the newly machined opened port.

This bike is a daily rider and will be keeping the standard carb and oil injection system so we decided to simply polish the inlet. Opening it out and still keeping the standard rotary valve induction is a tricky process. The basic mechanics of a rotary valve system mean that the crank web must fully seal the inlet when the crankcase has taken a new charge of air/gasoline.

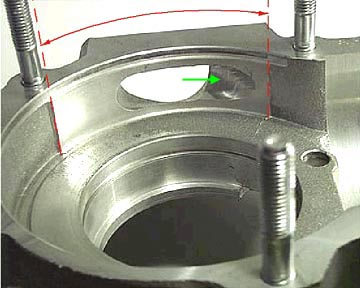

In the shot above you can see the machined contact area of where the crank web seals with very low tolerances against the casing noted in red. There is very little machined surface to either side of the opening and if you open this inlet out beyond the machined area the rotary valve will no longer function and neither will your engine. If you open it out the length you will affect the port timing and intake duration. Note: there is a machined area that looks almost like someone drilled it out from above at a slight angle towards the barrel. This is not someones previous attempt at tuning your casings - , it is standard (shown with green arrow).

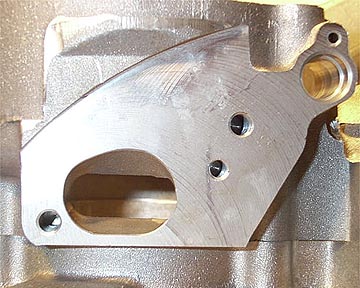

Above is a shot of the standard carb mount face on a P-Series. The intake tapers down to the crank web. Anyway, once again this could be opened out a little to improve the gas flow, but we are just going to polish the rough face of the casting. The large hole in the upper right hand corner of the machined face is for the oil metering device.

It is a little strange because the bottom of a P carb venturi is round and overlaps the intake on the casing. For whatever reason the casing intake is larger then the carb venturi. I suppose it is better than being smaller than it. Next Section --> |

|||||||||||||||