|

|

|

|

|

|

|

||||||||||||

Lambretta Engine WorkGeneralLambretta |

Removing a Lambretta FlywheelThe flywheel helps the engine idle properly, has an integral fan, and rotates magnets around the stator to produce AC power. To remove it you'll need:

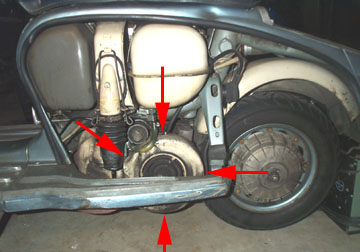

Remove the

left hand side panel to get access to the motor. Then remove the screws

holding the fan shroud to the engine casing. I seem to remember this

can be done without removing the left side floor board extension, but

these pictures are of a motor not currently in a frame so I could be

mistaken.

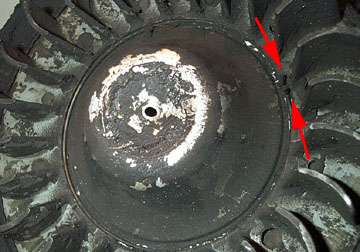

Once the shroud is removed the center cover and the flywheel are visible. The center cover is held in place by a wire retaining ring. Squeeze the two ends together and the ring can be removed.

The center cover has slotted ears and may have to be rotated around until the ears align with slots in the flywheel before it can be removed.

Using a flywheel holding tool and a socket and driver, loosen the 17mm central nut. Remember this is a left hand threaded nut which means it operates in the reverse way as a normal nut. Rotating it clockwise actually loosens it.

Remove the nut and the shake proof washer. Make sure all the internal threads are clean before fitting the puller.

Carefully thread the puller in place. Be sure to get it nice and deep in the bore so that you have more thread to pull against. Sometimes it is necessary to use the flywheel holding tool to get the puller nice and deep.

Use adjustable wrenches to tighten the center part of the puller and keep the outside from turning. You should hear a pop when the flywheel is pulled off the tapered end of the crank.

Carefully lift the heavy flywheel clear of the casing. If you feel some resistance it is likely to be the magnets on the flywheel trying to pull towards the steel on the coil supports. Once the flywheel is clear have a look in the slot in the crank taper for the woodruff key. Sometimes it will be stuck in place and can be left but if it is loose, take it out and save it for the rebuild (or just use a new one).

With the flywheel out of the way the stator is accessible for maintenance or replacing entirely. Next Section --> |

|||||||||||||||||