VespaAutomatic ProjectAutomatic Engine |

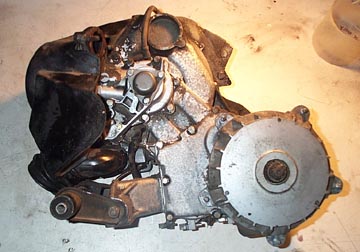

Automatic Engine

This is a weird engine to look

at with so much of my experience revolving around the typical small

frame and large frame motors from the 80s and before. A big thank you

goes out to the guys at American Scooter Center who sold me this engine in

the first place.

My first scooter (OK...moped)

was a Vespa Bravo so I have some familiarity with the idea of a belt

drive and pulleys that change diameter as speed increases. I plan to

convert this motor to an electric start system that was an option. The

main parts that will need changing are the flywheel and adding an

electric start motor to the blanked out area on the motor casing.

The PK 125 Automatica was only

produced for Europe. It is an ideal donor as it has all the things in a

current automatic such as an oil injection option, reed valve intake,

electric start option, and at 125cc it should be able to keep up with

traffic. I don't yet know if standard small frame kits will fit this

bike - we'll see.

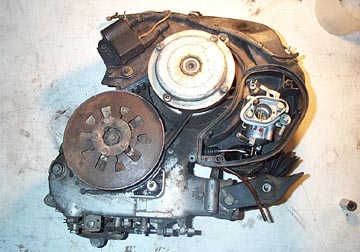

Still a very odd looking

thing...

The intake the the cylinder is

through a stock cranckase reed valve. As far as I know there is no

other Vespa before the ET2 that ever used a reed valve. The small coat

hanger looking thing is actually the throttle arm.

The barrel and piston are also

much more modern than I have seen on a stock Vespa. Crankcase transfers

are much bigger than a typical small frame (or any 125cc) and the

barrel is rotated in the same manner as a smal frame, with the exhaust

facing up. The barrel is aluminum and from what I can tell it has a

Nicasil plated bore...I could be wrong.

The rear brake is a single

brake shoe that is apparently impossible to find.

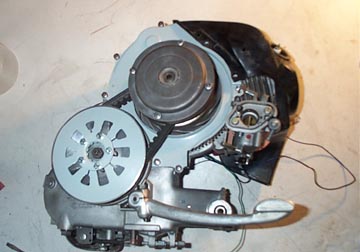

After a rebuild and a clean

this is the final result so far. See more in the rebuild sections.

The guys at SIP were

generous enough to ship me a Vespa PK50 Automatica exhaust they had in

stock, but I soon found it was a little different. It left about a 1.5"

gap between the cylinder and the exhaust stub. I have just started

learning how to weld so I thought this would be the perfect project.

The shot above shows the

aluminum exhaust stub with blue tape over it to keep things clean, and

then the exhaust leader stub to the right.

My welding skills aren't great

(yet), but after measuring and cutting I managed to fabricate the

following filler piece complete with flanges. After this shot was taken

I Dremeled out the inside for a smooth flow.

...and bingo - it fits!! This

was the last step before I could bench test the motor so soon it will

be running again and I can test it all out. Next Section --> |

|||||||||||||||||