|

|

|

|

|

|

|

|||||||||||

ElectricalTiming tools |

Timing ToolsThis section will show you how to build some tools which are very helpful for timing points ignition engines. TDC Tool:The first tool to make things easier is a top dead center tool. With the help of a degree disk this will allow you to find the point at which the piston has reached the upmost point of its travel (top dead center). The reason that this is important is that all timing on 2 stroke engines can be defined as a certain amount of degrees before top dead center (BTDC). You will need:

The first step is to remove the central electrode from the spark plug. Start by bending off the electrode at the bottom of the spark plug (arrowed in red). Then destroy the ceramic insulation above the metal body of the plug (arrowed in blue).

Once the insulation and electrode have been removed, you will need to remove some ceramic insulation from the inside of the plug. The idea here is that you will need enough room to thread the 1/4" bolt through the metal body of the spark plug. I used an old drill bit on mine to open out the electrode passage. This is not great for the bit so use an old one if possible.

With everything hollow inside the spark plug body, thread a single nut onto the bolt. The nut diameter must be large enough to stop the head of the bolt going through the plug body, but small enough to allow a standard plug tool to still engage the hexagonal area of the plug body.

Once the threaded bolt is set into the body you should have something like this. Tighten the nut so that the bolt cannot move. You should have about 1/2" to 3/4" of threaded bolt sticking out of the bottom of the plug body.

Above are two shots of an old VBA head with the TDC tool in place. The idea is that as you turn the engine over by hand the piston is stopped from reaching TDC as the piston moves up towards the head. With the help of a degree disk you can then rotate the engine backwards until it hits again and compute where TDC is. For more info on this procedure please see the points timing page.

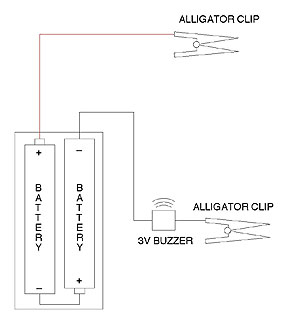

Continuity Tester:When timing a points engine, it is very helpful to have an audible or visual helper to let you know when the points separate. This is the exact point when the spark will fire and with the help of a degree disk the timing can be accurately set. The one that I built used a buzzer so that I could use it outside in bright light, but you can easily substitute a light bulb for the signal if you prefer.

I built mine with basic parts from Radio Shack and it cost about $10. I decided to use insulated alligator clips on the contacts so that I could connect to specific areas of a bike without risk of touching the wrong contact. This tool can also be used to trace wires in the wiring loom. You will need:

The idea is to create a circuit that is completed when the alligator clips are in contact with each other, or are bridged by a conductive surface.

Above are the parts to construct the tester. You basically solder the connections together and attach the alligator clips as shown in the drawing below. Be careful when you store the tool as if anything bridges the clips the buzzer will sound and run the batteries dry.

Degree disk:This tool in conjunction with the TDC tool makes timing easy. It allows you to see the flywheel rotation in degrees and accurately set the timing to the standard specification or adjust it for a kit or other tuning option. I have included a downloadable .pdf file below and although the degree increment text does not print wonderfully, it will do the job. Basically just download the file, stick it on to some thin card so that it keeps its shape, and cut out the disk. I find it is really easy to attach this to any flywheel with a simple magnet over the central circle. Also for easy reference I have included most common points ignition stock Vespa timing specs in degrees BTDC. To see how to use this tool, check out the points timing page. |

||||||||||||||||