|

|

|

|

|

|

|

||||||||||

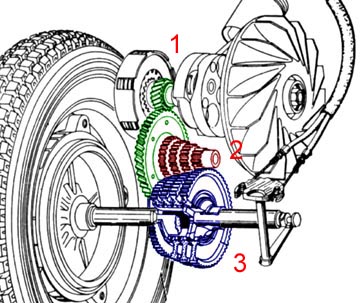

Vespa Large Frame GearingThe Vespa gearbox has used basically same set up since the first bike rolled off the assembly line. Small frames, wide body bikes, and large frames all use variations of this system. Below is an overview of a typical large frame Vespa gearbox.

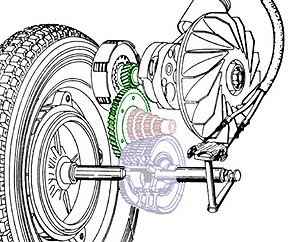

The Primary Drive

This is where the Vespa gearbox is less flexible then the Lambretta gearbox. In most cases the large helical gear and the smaller clutch gear must be changed as a pair. In comparison, a Lambretta gearbox allows each of these two items to be changed independently because a larger chain can take up the slack. With a Vespa, if one gear diameter increases the other must decrease because since they physically meet, their relationship must always be the same. There are kits on the market from Polini and Malossi that require drilling the rivets out of the gears and allow you to retain the standard Christmas tree gear cluster, while changing the primary drive to a higher, non-standard ratio. A list of some combinations are listed on the Vespa gear calculator page by small gear/large gear teeth (ex 23/65 for a P200E).

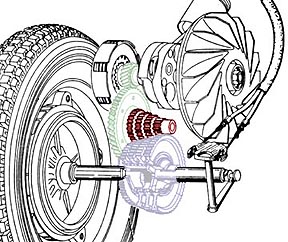

The Input Shaft

Other than a few exceptions the input shaft gears and the separate gears on the output shaft must be changed as a pair. An exception is the T5 4th gear that can be installed in a P200 standard box to give higher RPM in 4th gear. Most after market expansion chambers create more power at higher RPMs than the standard exhaust, but less power than a standard exhaust at lower RPMs. There is a larger gap between the P200E 3rd and 4th gears than any other gear gap. This means that with an expansion chamber you may not have the power to reach the type of RPMs the pipe needs to perform well in 4th gear. Surprisingly if you make the gap smaller you may actually have a faster top speed.

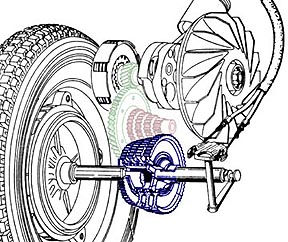

The Output Shaft

The output shaft gears are independently machined but should always go in as a group. This is the final drive, and a small machined cross locks each gear rotation independently to the output shaft rotation which is rigidly attached to the rear wheel. So all the gears spin when the bike is moving, by rotating freely on the output shaft, but only one gear at a time drives the shaft. The metal cross is moved up and down the output shaft by the gear twist grip on the handlebars. The next section allows you to mess around with different gearing options. Keep in mind that some of the combinations involve drilling out the rivets of the clutch drive which is a bit of a pain. Next Section --> |

||||||||||||||||

Gearing |

||||||||||||||||